Energy storage

Energy storage

Global energy demand is climbing rapidly due to population growth and continuing industrialization. Renewable energy is expected to provide a central solution to our need for a sustainable fuel. Many countries have announced plans in the use of clean energy. In 2020, renewable energy targets have been adopted in 169 countries at the national or provincial level and renewables had provided more than 26% of global electricity generation. However, major challenges presented by renewable energies, such as fluctuations in output, unavailability (e.g. sunlight in the night) and unpredictability (e.g. wind power), limit their implementation. As a solution to these problems, energy storage systems, acted as a buffer between power generation and grid, make a real difference in effective ways to improve power quality, stability and reliability of transmission and distribution system. For example, battery system (e.g. lithium battery, redox flow battery, or combination of these two) has the potential to provide many hours of high quality power from the kW- to MW- scale for grid services (e.g. load balancing and peak shaving). In a remote or weak grid area, utilisation of battery technology will allow users to store locally generated electricity and facilitate renewable energy deployment, and to use battery system as a stand-alone power system to replace diesel generators.

Energy storage technologies can be grouped into five categories in terms of the forms of the stored energy, including

- Potential / Kinetic: pumped hydro, compressed air energy storage, flywheels

- Chemical: biofuel, hydrogen storage, power to gas

- Thermal: thermal energy storage (general), ice storage, phase-change materials

- Electrochemical: rechargeable batteries, hydrogen and fuel cells

- Electric-magnetic: supercapacitor, superconducting magnetic energy storage

The focus of this research group is predominantly on electrochemical energy storage technologies, including redox flow batteries, electrolysers for hydrogen production, fuel cells and supercapacitors. Activities are mainly directed at fundamental research at laboratory scale, particularly in the areas of catalyst development, electrode materials, fluid dynamics and electrolyte additives and composition.

Group members

Current

- Research lead: Prof. Xiaohong Li - Professor of Energy Storage

- Dr Zhenyu Zhang - Lecturer in Renewable Energy

- Mikey Jones - Postgraduate funded by EPRSC Doctoral Training Partnership Studentships

- Cheng Lyu - Postgraduate funded by China Scholarship Council and University of Exeter PhD Scholarships

- Jack Corbin - Postgraduate funded by the University of Exeter PhD Scholarship

- Ida Nawrocka - PhD student

Alumni

- Dr Yanping Du - Senior Lecturer in Energy Storage and Conversion

- Dr Adeline Loh - Postdoctoral Research Fellow

- Dr David Trudgeon - Postdoctoral Research Fellow

- Zheng Huang - Postdoctoral Research Associate

- Jack Hughes - Postgraduate by Published Work

- Callum Turnbull - Postgraduate funded by EPRSC Industrial Centre for Doctoral Training for Offshore Renewable Energy (IDCORE)

- Prof Yanyu Liang - Academic Visitor

Facilities

The group has capabilities in a range of areas, from material synthesis, fabrication and characterisation to fundamental electrochemical analysis and small device testing. For further details of the research facilities available please visit our dedicated 'Energy storage research facilities' webpage.

Research areas

Hydrogen is expected to play a key role in meeting the need for clean fuel for both energy storage and transport purposes. Electrolysis of water is a clean method of producing hydrogen fuel. Currently, existing alkaline water electrolysis plants operate at low current densities (around 0.25 A cm-2) and can only achieve energy efficiencies of around 60%.

Proton exchange membrane (PEM) water electrolyser systems demonstrate a substantial increase in efficiency and are commercially available, but are expensive. Our research aims to develop AEM electrolysers utilising non-precious metal catalysts to enable reduced overpotentials for electrode reactions compared to acidic systems, whilst maintaining improved efficiency.

The focus of the work is therefore on developing cost effective, efficient and stable catalysts for both oxygen evolution reaction at anode and hydrogen evolution reaction at cathode, the design and fabrication of membrane electrode assemblies (MEA) and the development of efficient AEM electrolysers. Ultimately, AEM electrolysers can lead to cheaper hydrogen production.

Contacts:

Selected publications:

- Development of Ni-Fe based ternary metal hydroxides as highly efficient oxygen evolution catalysts in AEM water electrolysis for hydrogen production, Loh A, Li X, Taiwo OO, Tariq F, Brandon NP, Wang P, Xu K, Wang B. International Journal of Hydrogen Energy, 45 (2020) 24232-24247.

- Density Functional Theory Study of NiFeCo Trinary Oxy-hydroxides for Efficient and Stable Oxygen Evolution Reaction Catalyst, Ullah H, Loh A, Trudgeon D, Li X. ACS Omega, 5 (2020) 20517-20524.

- High surface area coatings for hydrogen evolution cathodes prepared by magnetron sputtering, Zhang X, Hampshire J, Cooke K, Li X, Pletcher D, Wright S, Hyde K. International Journal of Hydrogen Energy, 40 (2015) 2452-2459.

- A comparison of cathodes for zero gap alkaline water electrolysers, Pletcher D, Li X, Wang S. International Journal of Hydrogen Energy, 37 (2012) 7429-7435.

- Prospects for alkaline zero gap water electrolysers for hydrogen production, Pletcher D, Li X. International Journal of Hydrogen Energy, 35 (2011) 15089-15104.

- Nickel based electrocatalysts for oxygen evolution in high current density, alkaline water electrolysers, Li X, Pletcher D, Walsh FC. Physical Chemistry Chemical Physics, 13 (2011) 1162-1167.

Redox flow batteries (RFBs) utilise one or more redox couples to store energy in electrochemical form. The electrolyte is stored in tanks external to the cells and pumped through the system during operation. Currently, commercialised RFB technologies such as vanadium and zinc-bromine, are complex and expensive, largely due to the requirement for costly ion exchange membranes.

The energy storage research group has particular experience in membrane free RFB systems including hydrogen-bromine, soluble lead acid, zinc-air and zinc-nickel chemistries. These have great potential to provide cost-effective alternatives to currently available technologies by removing the requirement for ion exchange membranes, simplifying cell design and utilising low cost and abundant active materials.

Research in this area is focussed on the development of novel electrode and catalyst materials, electrolyte additives and composition, and optimisation of cell design. Through synergistic implementation of findings in these areas, efficient, durable and cost effective RFB systems can be created.

Contacts:

Selected publications:

- The Influence of Zinc Electrode Substrate, Electrolyte Flow Rate and Current Density on Zinc-Nickel Flow Cell Performance, Trudgeon D, Loh A, Ullah H, Li X, Yufit V, Brandon N, Liu M, Kong L. Electrochimica Acta, 373 (2021) 137890.

- The effect of electrolyte and additive concentration on zinc–nickel flow cell performance, Trudgeon DP, Li X. Electrochimica Acta, 367 (2021) 137479-137479.

- Screening of effective electrolyte additives for zinc-based redox flow battery systems, Trudgeon D, Qiu K, Li X, Mallick T, Taiwo OO, Chakrabarti B, Yufit V, Brandon N, Crevillen-Garcia D, Shah A. Journal of Power Sources, 412 (2019) 44-54.

- The characteristics and performance of hybrid redox flow batteries with zinc negative electrodes for energy storage, Arenas LF, Loh A, Trudgeon DP, Li X, Ponce de León C, Walsh FC. Renewable and Sustainable Energy Reviews, 90 (2018) 992-1016.

- Zinc-based flow batteries for medium and large-scale energy storage, Li X, de Léon C. P, Walsh FC, Wills RGA, Pletcher D. Advances in Batteries for Medium and Large-Scale Energy Storage: Types and Applications, (2015) 293-315.

- Progress in redox flow batteries, remaining challenges and their applications in energy storage, Leung P, Li X, Ponce de Leon C, Berlouis L, Walsh FC. RSC Advances, 2 (2012) 10125-10156.

Supercapacitors possess high power densities and extremely long cycle stability and reliability. As such, they are a promising solution to replace or compliment batteries for many applications, electric vehicles and portable devices for example, which require high rate charge / discharge capabilities. However, the energy density of commercially available electrochemical double layer capacitance (EDLC) supercapacitors is limited as energy is stored solely by reversible adsorption / desorption processes of ions on the surface of the electrodes.

Pseudo-capacitors have potentially much higher energy density as the reaction take place not only at the electrode surface, but also in the bulk material. Research is therefore focussed on the development of pseudo-capacitive electrode materials such as transition metal oxides and conducting polymers, in order to improve energy density while maintaining the high rate capabilities and long lifetimes associated with supercapacitors.

Contact:

Selected publications:

- 3D Hierarchically Structured CoS Nanosheets: Li+ Storage Mechanism and Application of the High-Performance Lithium-Ion Capacitors, Wang Y, Liu M, Cao J, Zhang H-J, Kong L-B, Trudgeon DP, Li X, Walsh FC. ACS Applied Materials & Interfaces, 12 (2020) 3709-3718.

- High Volumetric Energy Density Capacitors Based on New Electrode Material Lanthanum Nitride, Zhang W-B, Ma X-J, Loh A, Li X, Walsh FC, Kong L-B. ACS Energy Letters, 2 (2017) 336-341.

- Three-dimensional graphene oxide/polypyrrole composite electrodes fabricated by one-step electrodeposition for high performance supercapacitors, Cao J, Wang Y, Chen J, Li X, Walsh FC, Ouyang JH, Jia D, Zhou Y. Journal of Materials Chemistry A, 3 (2015) 14445-14457.

- Materials and fabrication of electrode scaffolds for deposition of MnO2 and their true performance in supercapacitors, Cao J, Wang Y, Li X, Walsh FC, Ouyang J, Jia D, Zhou Y. Journal of Power Sources, 293 (2015) 657-674.

- Synthesis and characterisation of M3V2O8 (M = Ni or Co) based nanostructures: a new family of high performance pseudocapacitive materials, Liu M, Kong L, Kang L, Li X, Walsh FC, Xing M, Lu C, Ma X, Luo Y. Journal of Materials Chemistry A, 2 (2014) 4919-4926.

- The specific capacitance of sol–gel synthesised spinel MnCo2O4 in an alkaline electrolyte, Kong L, Lu C, Liu M, Luo Y, Kang L, Li X, Walsh FC. Electrochimica Acta, 115 (2014) 22-27.

Lithium-ion batteries have been extensively used in portable devices for many years, and their usage continues to increase, particularly with the escalation of uptake of electric vehicles. In order to enable the continued proliferation of lithium-ion batteries it is vital that efficient and cost-effective recycling methods are established. A range of recovery methods are under investigation including ultrasonic separation, heat treatment, chemical leaching and bio leaching processes to recover valuable and scarce metals including lithium, cobalt, manganese, nickel and copper.

Contact:

Although Lithium-ion batteries (LIBs) have achieved big success as electrochemical energy storage systems for electronic devices, electric vehicles and beyond in the past decades, the demands for higher energy and power densities, higher charging rates, longer cycle life, and better safety are still not satisfied.

We develop novel high ionic conductivity solid-state electrolyte materials, such as ceramic, polymer/salt and composite materials (with additives). By adopting lithium metal anode (or anode-free), the energy density of lithium-ion batteries could be significantly improved. In situ/ex situ electrochemical analysis and advanced characterization methods are combined to evaluate the properties of electrolytes. Meanwhile, novel synthesis methods are developed to lower the cost and enable large scale fabrication.

Contact: Dr Zhenyu Zhang

Projects

This project brings researchers from across the GW4 Alliance of Bath, Bristol, Cardiff and Exeter universities alongside Swansea, South Wales, and Plymouth and will work with 25 civic and industry partners to maximise the enormous potential of the Southwest of England and South Wales hydrogen ecosystem.

Total grant is £4m (£2.5m from EPSRC and £1.5m in additional funds and in-kind support from civic and industry partners).

Contact: Prof. Xiaohong Li

Related News: Multimillion pound investment to develop hydrogen supercluster in South West England and South Wales

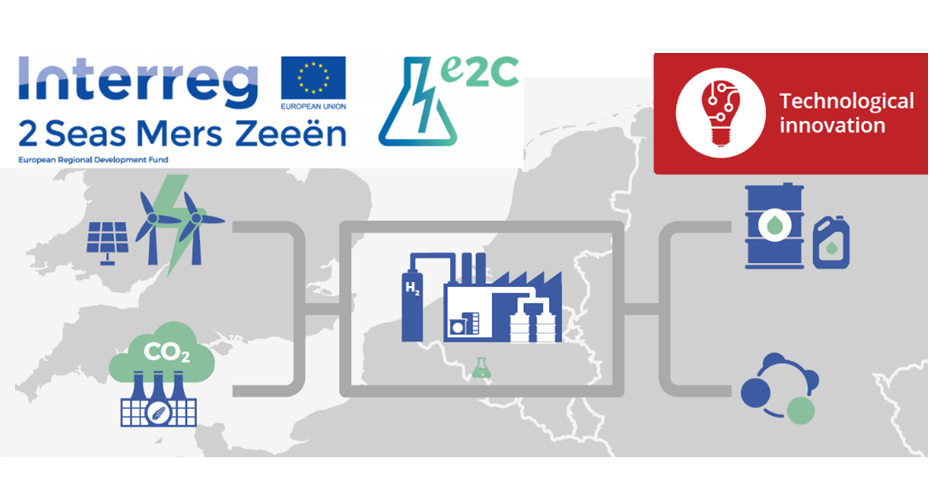

This project is funded by the Interreg 2 Seas Programme and is led by TNO. The overall objective of the project is to stimulate investment in and implementation of Power-to-X technologies by developing innovative direct and indirect conversion processes for the chemical industry, while making use of renewable electricity and lowering the carbon footprint. With these technologies, valuable fuels and platform chemicals can be produced from renewable raw materials while decreasing costs and increasing flexibility. The aim is to develop at least two pilot demonstrators and two bench scale pilot installations with supporting feasibility evaluations, thereby lowering the risks of investment for companies and positioning the 2 Seas region as an innovation leader in Power-to-X sustainable technologies. Within this, the University of Exeter is focused on anion exchange membrane (AEM) water electrolysis, involving the development of catalyst materials as well as design and fabrication of membrane electrode assembly (MEA) and lab-scale AEM cells.

Project Partners:

- TNO, Netherlands Organisation for Applied Scientific Research

- VITO, Flemish Institute for Technological Research

- Technical University Delft

- University of Exeter

- University of Antwerp

- University of Lille

- University of Sheffield

Contact: Prof. Xiaohong Li

The project aims to develop a low-cost, high efficiency membrane-free redox flow battery (RFB) system using hydrogen and bromine redox couples. RFBs are a key enabling technology for the energy transition. However, mass market introduction of RFBs has been hampered by various factors including material scarcity and cost, limited catalyst lifetime, expensive ion exchange membranes, system complexity and safety issues. The development of an economically viable, environmentally benign and sustainable RFB storage system is therefore eagerly awaited.

MELODY will develop a sustainable RFB technology that is able to reduce the costs of electricity storage to an absolute minimum. The membraneless design eliminates the need for expensive membranes, reduces the internal resistance of the cells and simplifies system design. The hydrogen and bromine active materials are abundantly available and not geographically restricted. Furthermore, catalyst degradation is averted by eliminating the crossover of species between the electrodes. The focus of the energy storage research group at the University of Exeter is the development of suitable high performance carbon based bromine electrode materials for the hydrogen-bromine RFB system.

Project Partners:

- Technical University Delft

- ETH Zurich

- University of Exeter

- Technion Israel Institute of Technology

- TFP Hydrogen Products

- Elestor

- Fraunhofer Institute for Chemical Technology

- Shell Global Solutions International BV

Contact: Prof. Xiaohong Li

Redox flow batteries (RFBs) utilise one or more redox couples to store energy in electrochemical form and employ flowing electrolytes. Currently, commercialised RFB technologies such as vanadium and zinc-bromine are complex and expensive, largely due to the requirement for costly ion exchange membranes. This University of Exeter led EPSRC funded project focussed on the development of a membrane free RFB utilising a zinc negative electrode and a nickel positive electrode which has potential to be a cost effective alternative to existing systems due to the relatively low cost of active materials and cell components.

The zinc electrode is subject to parasitic hydrogen evolution and zinc electrodepositions, both of which are detrimental to system efficiency and durability. Research conducted within the group has demonstrated that these issues can be averted by the use of additives to the electrolyte, careful selection of electrode substrate materials and control of the electrolyte flow regime. The capacity of the zinc-nickel RFB is partially limited by the nickel electrode, which also suffers from undesirable oxygen evolution. This may be overcome by the design of high surface area electrode materials with increased loading of active materials. These measures improve the performance and durability of the zinc-nickel RFB, facilitating the scale up of the technology for grid applications in an efficient and cost-effective manner, ultimately benefitting power producers, industry and domestic consumers.

Project Partners:

- University of Exeter

- Imperial College London

- University of Warwick

- C-Tech Innovation Ltd

- WhEST – Watt-hour Energy Storage

Zinc-Nickel Redox Flow Battery for Energy Storage website >

Contact: Prof. Xiaohong Li

Supported by funding from the Department of Business, Energy and Industrial Strategy (BEIS) and organised by the Royal Academy of Engineering, this project features a newly formed UK–Germany coalition that seeks to address the challenge of deployment of energy storage solutions and approaches to public interaction. In this project, the research focus is on low-cost but highly efficient catalysts for AEM water electrolyser for green hydrogen production, as well as durable electrodes with high capacity for RFB application.

The project is a joint collaboration that will provide opportunities for the project partners to utilise their strong knowledge bases to conduct advanced research in electrode development and computational modelling. The project participants will also form an innovation hub in the research area of AEM electrolysers, which will trigger further developments and contribute to the competitiveness of Europe in the area of clean and sustainable energy storage solutions.

Project Partners:

- University of Exeter

- Helmut-Schmidt-University (HSU), Hamburg

Contact: Prof. Xiaohong Li